Published and edited by: Chen Machuan

WUST News - Stephen Mweemba, an international student at the Wuhan University of Science and Technology (WUST) has published a high-impact paper in the prestigious international journal Energy (Impact Factor: 9; Category 1, Chinese Academy of Sciences, Engineering and Technology). The paper, titled "Thermomechanical analysis of a coke dry quenching furnace," features Mweemba as the first author and was completed under the guidance of Professors Gu Huazhi and Zhang Meijie from the Faculty of Materials at WUST.

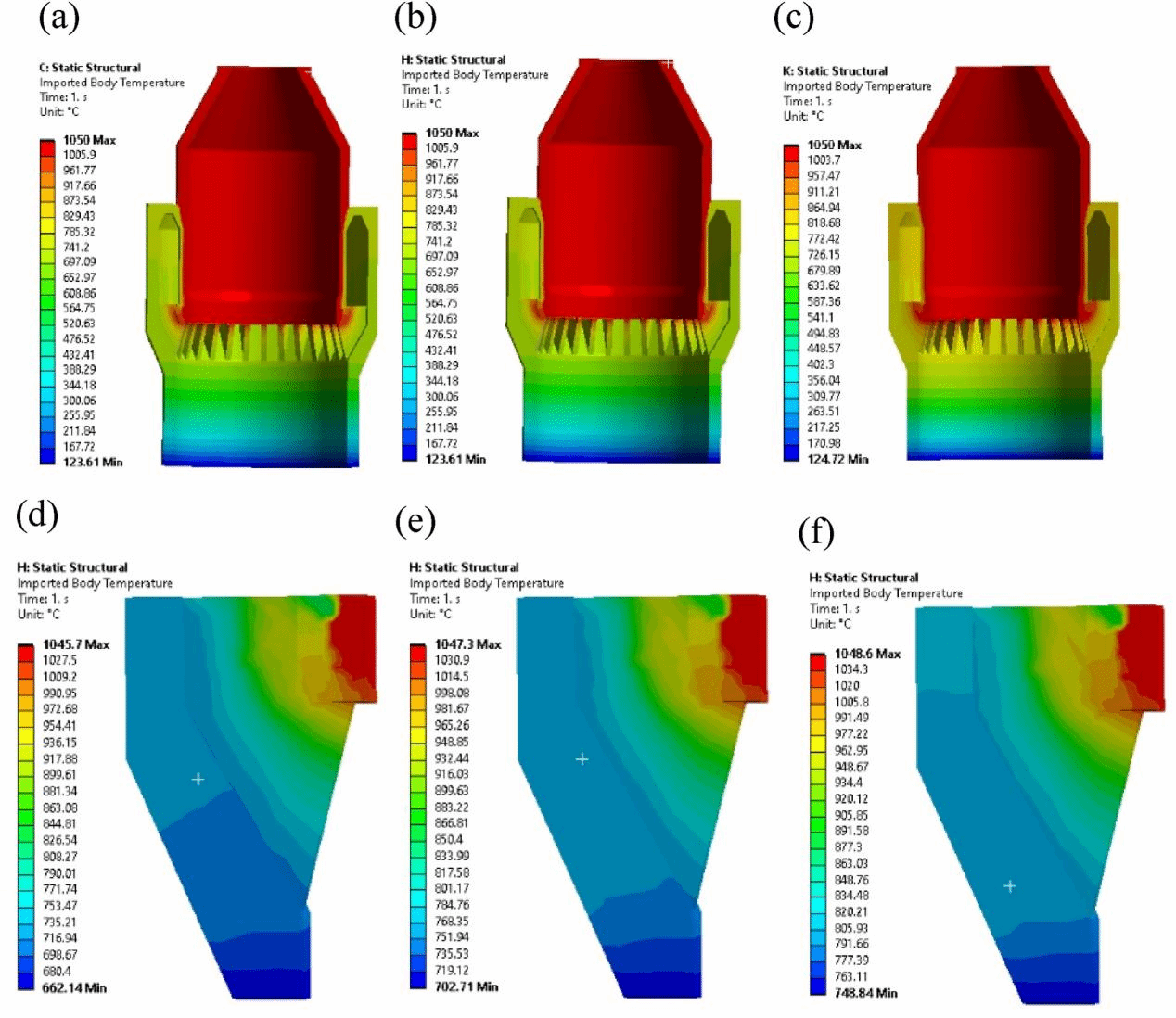

The Coke Dry Quenching (CDQ) process is a valuable method for reducing the carbon footprint of coke production and improving coke quality. Extending the lifespan of the refractory materials within CDQ furnaces is critical for maximizing the energy efficiency of this process. In this study, researchers investigated how CDQ furnace operating conditions affect the degradation rate of the refractory lining. They conducted a coupled flow-thermal-solid numerical simulation and analysis on a 140-ton/hour CDQ furnace, examining the influence of gas flow, thermal boundary conditions, and other factors on the performance of the refractory lining.

The study revealed that gas flow, thermal boundary conditions, and the properties of the refractory materials have a significant impact on the thermal stress and deformation of the furnace lining. Specifically, reducing gas flow velocity lowers thermal stress but increases deformation. Conversely, increasing the thermal expansion coefficient of the refractory materials leads to greater thermal stress and deformation under the same boundary conditions. The analysis identified the base of the chute pillars as the area experiencing the highest thermal stress, followed by the inner surface of the annular flue. Elevated local temperatures on the inner wall of the annular flue can also contribute to increased thermal stress. These findings highlight the importance of temperature gradients, localized hot spots, and the physical properties of materials under operating conditions in determining the thermal stress and deformation of CDQ refractory materials. The research suggests that carefully controlling gas flow velocity and selecting appropriate materials can significantly extend the service life of the furnace lining.

Stephen Mweemba, a member of the 2021 cohort, is currently pursuing his doctoral studies in Materials Science and Engineering at WUST, having continued his academic journey after completing his master's degree under the supervision of Professor Zhang Meijie. He is now a doctoral student in the 2024 cohort. In recent years, WUST has prioritized the education of international students, continuously enhancing the quality of their training and promoting internationalization through optimized programs, a strengthened academic environment, improved advisor support, and the establishment of international academic exchange platforms.