Published by: Chen Machuan Editor: Chen Machuan

WUST News (Reporter: Chen Machuan) From May 14 to 16, the 2025 World Digital Education Conference was held in Wuhan, Hubei. Wuhan University of Science and Technology (WUST) showcased its Intelligent Refractory Material Bricklaying Robot Platform, which was developed by the School of Mechanical Engineering, at the Hubei Higher Education Digital Innovation Exhibition. The platform attracted considerable interest and praise from delegates representing dozens of countries and regions.

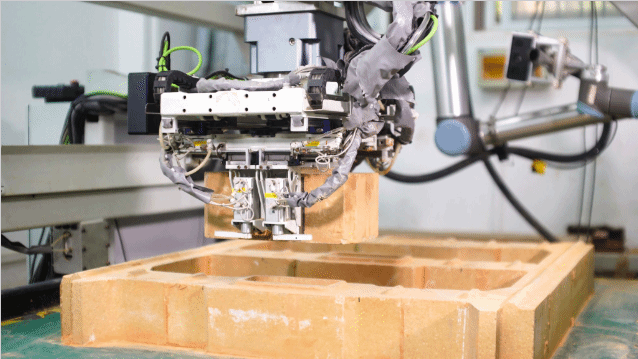

At the demonstration site, staff used 3D scanning devices to create digital models of refractory bricks in seconds, enabling virtual bricklaying simulations and robotic arm motion control. With a single touch to activate "one-click bricklaying", the robotic arm autonomously performed operations including grasping, applying mortar, and placing bricks with precision.

Refractory bricklaying is a critical technology for high-temperature equipment construction, directly impacting thermal resistance, sealing performance, and service life. However, manual bricklaying suffers from inefficiency and inconsistent precision due to factors such as heavy bricks, complex shapes, confined workspaces, and harsh environments. The WUST's solution, co-developed with Metallurgical Corporation of China (MCC), offers an innovative Chinese approach to this global challenge.

Professor Wang Zhaohui, the project lead from the WUST's School of Mechanical Engineering, explained that the robot can recognize over 1,000 types of irregular refractory brick with over 98% accuracy. Within a 0.5-meter-wide furnace chamber, the robot can effortlessly handle bricks weighing dozens of kilograms and complete identification, grasping, mortar coating, and placement with a precision of ±1mm—far surpassing traditional methods. The team's self-developed "one-click bricklaying" remote control system further enables intelligent full-process operations via virtual model-guided planning, significantly enhancing construction efficiency and safety.

"Designing and manufacturing such a robot platform requires the team to address challenges in structural design, intelligent perception, machine vision, motion planning, precision measurement, and system integration, involving interdisciplinary collaboration in mechanics, materials, and control," said Prof. Wang. After years of research, the team has independently mastered seven core technologies, including the design of robotic motion platform in confined spaces, virtual bricklaying planning for coke ovens based on digital twins, multi-level feature fusion for precise brick recognition and grasping, and adaptive mortar application with dual-arm collaborative control.

"These technologies provide a scientific basis for addressing key technologies common to intelligent robots throughout the metallurgical industry, with future applications in urban infrastructure renewal, large-scale bridge construction, and other high-end equipment manufacturing and construction industries," Wang added. The prototype has currently passed testing, and there are plans to establish a pilot platform at the university this year, followed by implementation in practical applications.

Leveraging this platform, the team has also developed an immersive teaching scenario combining "digital twins + on-site training": students first "build with blocks" on computers to construct virtual coke oven models, practice assembling over 1,000 types of special-shaped refractory bricks, and simulate the bricklaying process. They then operate real robotic arms in the laboratory to precisely execute tasks such as applying mortar and laying bricks. Finally, using the remote intelligent bricklaying control system, they complete bricklaying simulations and analyze operational data using AI, thereby improving operational techniques and forming a closed-loop training chain of "virtual simulation - practical verification - intelligent optimization", which helps students truly master the core technologies of robotic motion control.

In recent years, WUST has achieved a comprehensive digital transformation in education through the implementation of the education digitalization strategy. The foundational digital education infrastructure, such as smart education platforms, education data centers, and business information systems, has largely been completed. Classroom teaching digital monitoring systems, technology achievement transformation, and technology transfer information interconnection platforms are now in use. Numerous high-quality digital courses, first-class virtual simulation experimental teaching courses, and digital textbooks have been launched or are in the planning stage. Digital technology-related disciplines, such as artificial intelligence, intelligent construction, and intelligent mining engineering have been approved. These have fully empowered student learning, teacher teaching and research, school governance, and ecological innovation.